charpy impact tester speed|charpy impact tester for sale : import In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it . See more 立即下载. 每个人都有访问互联网的权利,您的语言绝不应该成为障碍。 在全球志愿者的不懈努力下,我们让 Firefox 浏览器拥有了超过 90 种语言版本。

{plog:ftitle_list}

webHappy Family, Conditions Apply – Season 1, Episode 10. When Hemlata and Mansukhlal's wedding anniversary party devolves into a life-and-death situation, all the .

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it . See moreIn 1896, S. B. Russell introduced the idea of residual fracture energy and devised a pendulum fracture test. Russell's initial tests measured un-notched samples. In 1897, Frémont . See moreThe quantitative result of the impact tests the energy needed to fracture a material and can be used to measure the toughness of the material. There is a connection to the yield strength but it cannot be expressed by a standard formula. Also, the . See more

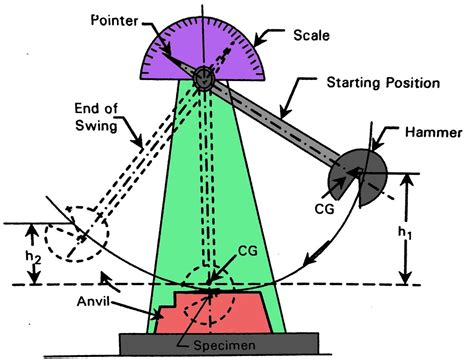

According to ASTM A370, the standard specimen size for Charpy impact testing is 10 mm × 10 mm × 55 mm. Subsize specimen sizes are: . See more• Izod impact strength test• Brittle• Impact force See moreThe apparatus consists of a pendulum of known mass and length that is dropped from a known height to impact a notched specimen of material. The energy transferred to the . See moreThe qualitative results of the impact test can be used to determine the ductility of a material. If the material breaks on a flat plane, the fracture was brittle, and if the material breaks with . See more

The impact energy of low-strength metals that do not show a change of fracture mode with temperature, is usually high and insensitive to temperature. For these reasons, impact tests . See moreThis makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test . Charpy impact test standards. ASTM E23, ASTM D6110, ASTM A370, ASTM D256. ISO 13479, ISO 148-1. EN 10045-1, EN ISO 179-1 Izod impact testing. While Charpy impact testing is widespread for metals, Izod impact testing is more often used for plastics and other softer materials. In Izod testing, the notched specimen is positioned vertically instead .Many resin products used in our daily lives, such as smartphones and car bumpers, require durability against impact. Some of the simplest methods used to determine the impact resistance and toughness of resin are Charpy and .

Impact tests on metals (Charpy, Izod conventional and instrumented) Tensile impact tests on metals; Wedge impact test for determination of the strength behavior of structural adhesives; . While influences such as fracture speed .The Charpy impact and notched impact test to ISO 179-1 and ISO 179-2 provide characteristic values for impact strength at high strain rates in the form of an area-related energy value. The tests are normally performed in normal climate or at low temperatures. Applications include: The comparison of different molding materials

A Charpy impact testing apparatus, a device with a pendulum with various locking points at specified heights and a fixture to hold the test specimen, is used to determine Charpy impact strength. . Impact testing cannot account for real-world impacts that may vary in speed, impact force, angle of impact, chemical exposure, corrosion effects .An impact test determines a material’s resistance to an impact event. It measures the amount of energy the material absorbs when it is hit by a high-rate load. The most common impact test methods are Charpy and Izod and are typically run using a pendulum impact tester. This can . nominal impact energy and impact speed) from an installed .An impact test consists of a striker hitting the test specimen to transfer a large force in a short time.You can use a drop tower or a pendulum tester to achieve such large forces.. A striker is dropped vertically from a height for a drop tower test and uses gravity to achieve the necessary impact energy. Similarly, in a pendulum test, the striker is fixed to an arm that swings like a .

Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. . Comparing the normalized length and diameter as a function of impact speed and post collision deformation . This research employs the Taguchi method and analysis of variance (ANOVA) to investigate, analyze, and optimize the impact strength of tough polylactic acid (PLA) material produced through fused deposition modeling (FDM). This study explores the effect of key printing parameters—specifically, infill density, raster angle, layer height, and print speed—on Charpy .In addition to the high energy impact models, Tinius Olsen manufactures a range of low energy pendulum impact testers that can also be easily changed from a Charpy to an Izod configuration. These testers come in a couple of capacities and are designed primarily for either plastics or metals impact testing.

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.

To determine the material resistance to impact from a swinging pendulum. Apparatus Required. Charpy testing machine, a rod of mild steel and a rod of carbonate steel. Charpy Test Specimens. Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be :Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.

The Charpy impact specimens of each material are immersed in a bath for 10 minu tes to reach thermal equilibrium at five separate temperatures ranging from 110oF (-79oC) to 212-oF (100oC). The specimens are quickly transferred to the Charpy testing machine, fractured, and the impact energy is measured. After

This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D .Freely selectable starting angles enable optimum test parameters, for example impact speed and energy loss at impact. After the test, the pendulum is automatically caught and returned to its initial position by a motor. .Pendulum impact tester HIT5P Pendulum impact tester HIT5.5P Pendulum impact tester HIT50P ContentPage 1 ZwickRoell - A striking solution 3 Find out more about ZwickRoell‘s pendulum impact tester product range and its levels of automation. 2 Product features of the HIT pendulum impact testers 4 Learn about the different functions and advantages

measurements normal endometrial thickness

Mechanical testing of welds. Philippa Moore, Geoff Booth, in The Welding Engineer s Guide to Fracture and Fatigue, 2015. 9.5 Charpy testing. The Charpy test measures the energy absorbed when a notched bar of material is struck with a fixed-weight pendulum swung from a given height. The absorbed energy (in joules) is also referred to as the impact toughness of the material. Study on Intrinsic Influence Law of Specimen Size and Loading Speed on Charpy Impact Test Materials (Basel). 2022 May 28;15(11):3855. doi: 10.3390/ma15113855. . Charpy impact tests were simulated using the modified JC model and JC failure model with the determined parameters. Reasonable agreements between the simulation and experimental .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the amount .

Charpy Impact Test ISO 179. . is raised to the appropriate height and is released so that it impacts the sample at a specified speed. A load-deflection curve is produced. Specimen size: Generally 4" x 4" plaques or 4" diameter disks. Any size or shape that will fit an impact tester.According to Indian Standard the speed of pendulum at the instant of striking shall be 4.5 - 7 m/s and the plane of swing of the striker shall be vertical and within 0.5 mm of the plane midway between the supports. . RELEVANT INDIAN STANDARD FOR CHARPY IMPACT TEST: IS 1598:1977-Method for Izod impact test of metals; IS:3766-1977- Method for . The Charpy Impact Test, developed by Georges Charpy in 1905, is one of the most widely used tests to determine a material's notch toughness. It has been critical in material selection, especially in industries where impact resistance is crucial, such as automotive, aerospace, and construction.What is the charpy impact test – The charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material’s notch toughness. The objective of the charpy impact test ?? To determine the material resistance to impact from a .

The MPM Charpy/Izod 9000 Series impact test machines can be used with pendulums in the 100 ft-lb to 700 ft-lb energy capacity range. . High speed photography has confirmed that the specimen halves that exit the front of the test machine rebound off the U-hammer exit channel and can interact with the striker several times after the fracture .Discover our Charpy/Izod Impact Tester NTCI-100 has specifications like Impact Speed & Energy (Charpy) of 2.9 m/s for 1J, 2J, 4J, 5J & 3.8 m/s for 7.5J, 15J, 25J, Impact Energy (Izod) of 3.5 m/s for 1J, 2J, 4J, 5J, 7.5J, 15J, 25J, Resolution of Impact Energy of 0.001 J, Power of 110V/ 220V, 60Hz/ 50Hz, etc. Buy Now! . Charpy/Izod Impact .Figure 5. Energy versus unit of time chart for Charpy Impact tests of AISI 304 welding. The reproducibility of the test was high, considering the resemblance between the test results with Charpy Impact tests conducted with impact velocity of 3.4 m/s, which was obtained in the previous study by Janssen et al. [15].

what is charpy impact test

charpy impact tester for sale

Resultado da 5 de abr. de 2017 · novayagazeta.ru. The investigation stated that there were small communities online — similar to the pages Palenkova had showed an interest in — that attracted teens with a game called "Blue Whale" or "Wake me up at 4:20." The types of accounts whose posts Palenkova was .

charpy impact tester speed|charpy impact tester for sale